Product designer Oscar Lhermitte with design studio Kudu have released the first topographically accurate lunar globe on kickstarter. The campaign has been launched a week ago and they have already raised nearly 3 times what they were asking for. The project involves the use of the latest data from Nasa’s lunar reconnaissance orbiter combined with advanced electronic and mechanical engineering alongside careful craftsmanship in mold making, triggering a place where design meets technology meets science meets art.

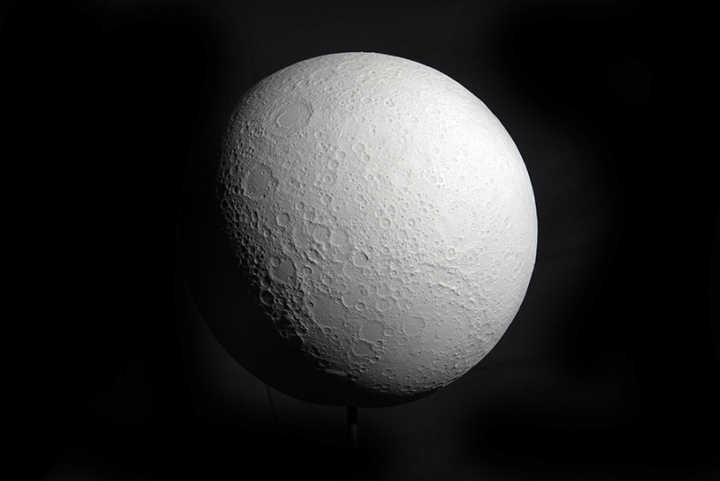

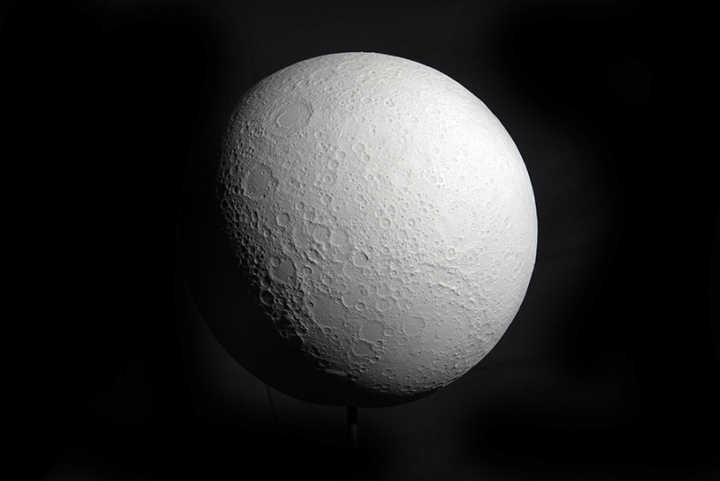

The results are a truly accurate 1/20 million replica of the moon with surface features in every detail. A ring of LEDs revolves around the globe, constantly illuminating the correct face of the moon and recreating the lunar phases as seen from earth. ‘Moon’ has three modes of operation: manual – allowing you to rotate the sun yourself, setting the lunar phase that you would like to see. Demo – letting you observe a synodic month in just 30 seconds. And live – synchronising itself with the current position of the real moon. All Moons are manufactured in their studio in London and individually numbered.

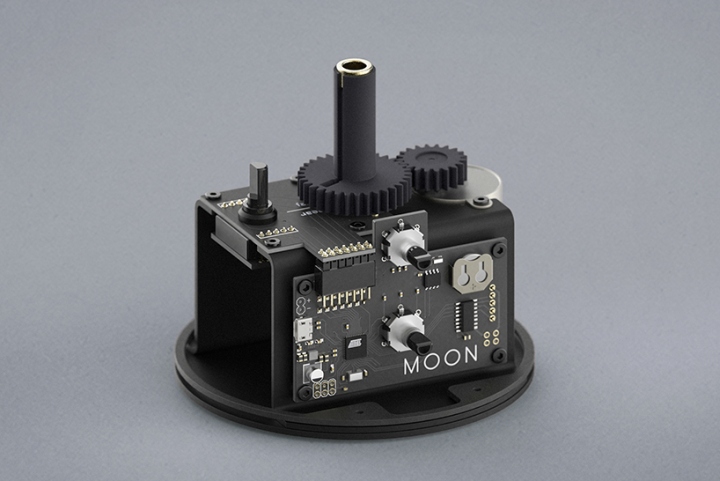

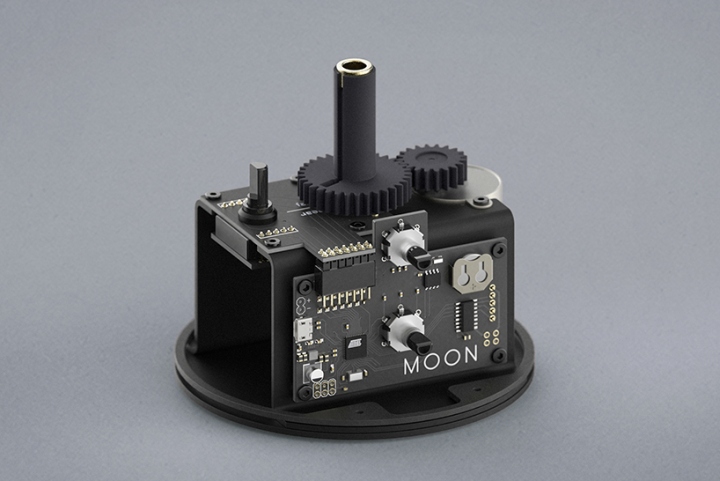

Moon is the result of a 4 years long project led by Oscar Lhermitte with Kudu where countless prototypes and testing has been carried out in the design process. Oscar Lhermitte was in charge of mapping the surface of the moon in 3D and of the overall design while Kudu worked on the mechanical parts and electronic engineering that mimics the sun and moon’s movement by precisely controlling the motion of the light.

In order to create the lunar globe, Oscar contacted the team at the institute of planetary research and they gave him access to their database. The data used are DTM (digital terrain model) and are constructed from stereo images. The images were then worked on to achieve the correct scale of terrain and make it spherical. One full moon was 3D printed in order to become the Moon master (the one the molds are then made from). They used an industrial nylon printer, with a layer thickness of 100 micron. The globes areroto casted from hard polyurethane resin and are pigmented in order to get a ‘concrete’ moon-like colour.

To make the LED ring rotate in sync with the actual moon, Kudu mimicked the sun and moon’s real time path by building and coding a custom computer that precisely controls the motion of the light. Its software and gearing system make sure it is perfectly in sync with the real-time lunar phase. The Moon computer has the exact same memory as the Apollo 11 computers that landed the first men on the moon.

Oscar Lhermitte and Kudu took great care in the design of the device, down to the smallest detail. The base is cut from thick steel, powder coated and the graphics are then screen-printed. The arm is CNC machined from aircraft-grade aluminium. This precision and attention to detail not only makes moon a scientifically accurate globe, but also an ambient light, designed to sit on a desk or shelf.

http://www.designboom.com/technology/oscar-lhermitte-kudu-moon-accurate-lunar-globe-04-21-2016/

Add to collection