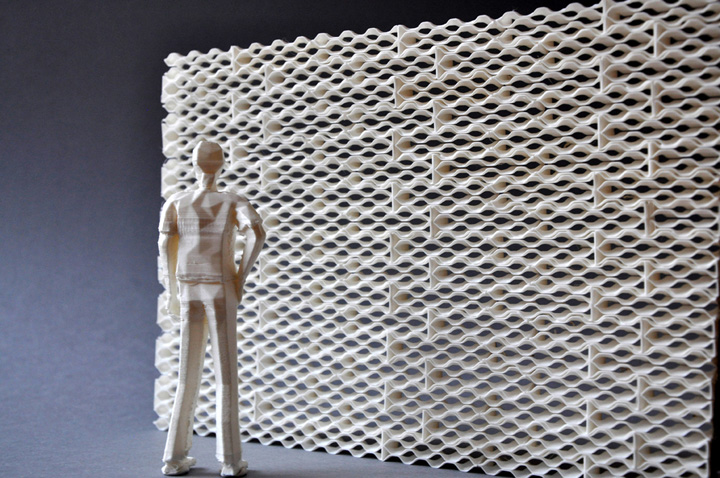

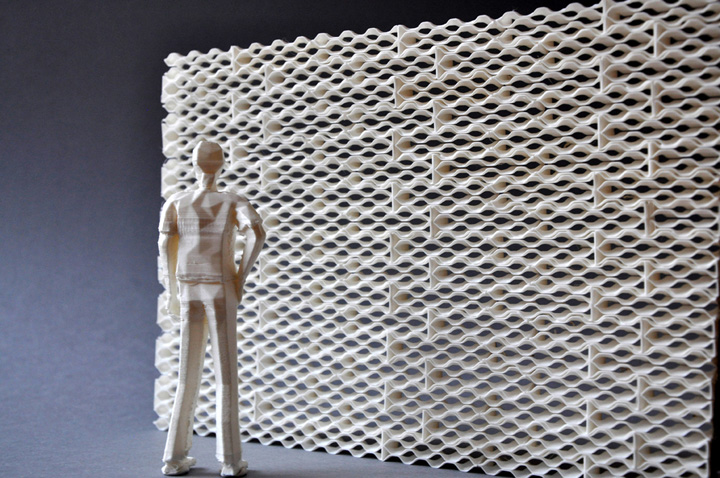

Building Bytes proposes a new method of fabricating architecture; desktop 3D printers become portable, inexpensive brick factories for large-scale construction. The first phase of this research was conducted during a 6-week residency at the European Ceramic Work Centre (sundaymorning@ekwc) which focused on how to 3D print with ceramics at the scale of architecture.

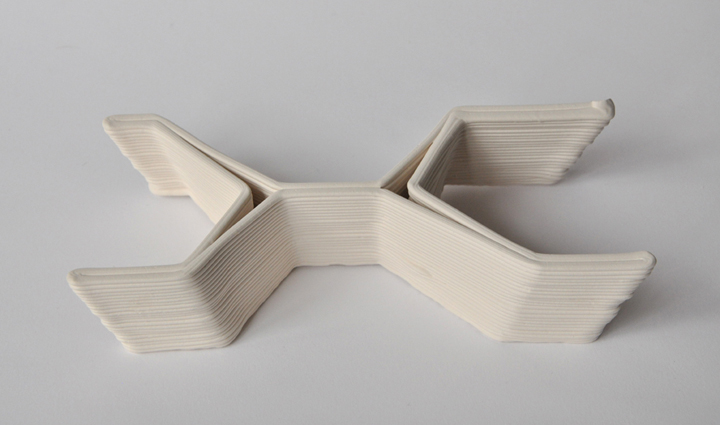

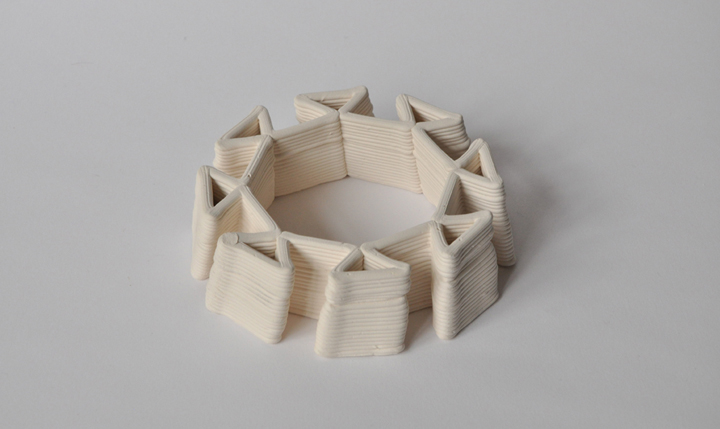

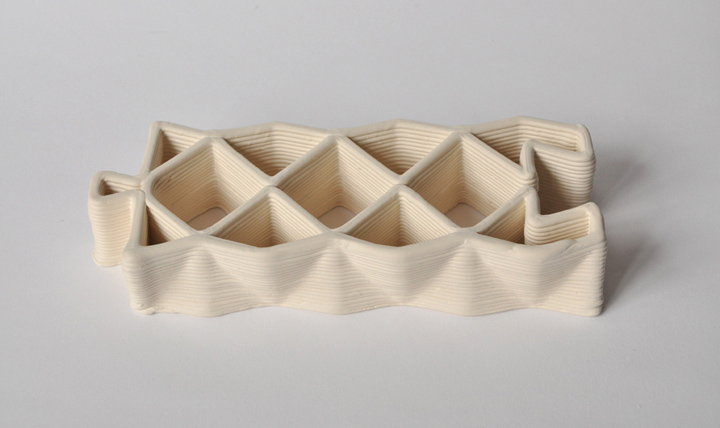

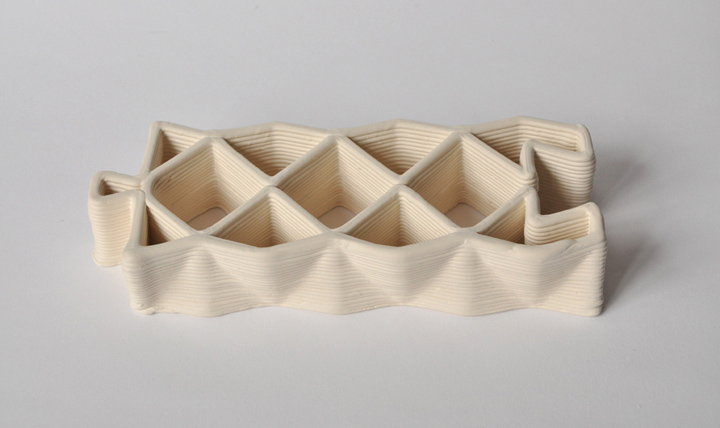

Working within fixed limitations (the size of a desktop 3D printer, capacity of the material storage system and the properties of clay) led to research into bricks. While the material and building unit are ancient and fairly universal, Building Bytes proposes to revolutionize the fabrication technique.

This fabrication system, including the materials and technology, allows Building Bytes to be accessible worldwide. The bricks are made from a liquid slip cast recipe of earthenware ceramics, which is typically used for casting molds, while a standard desktop 3D printer is connected to an extrusion system consisting of plastic cartridges and air pressure. The only customization is a material extrusion head that only requires minimal changes to existing printers.

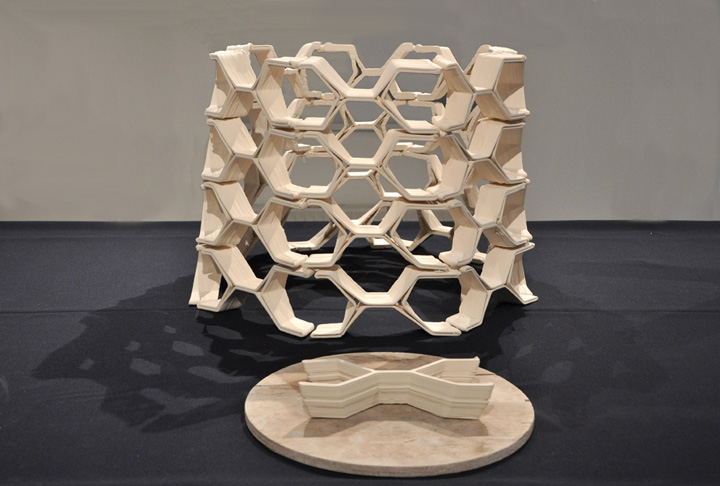

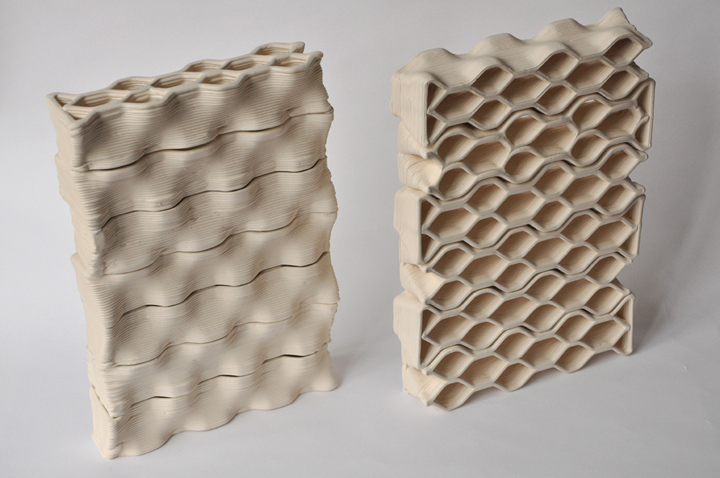

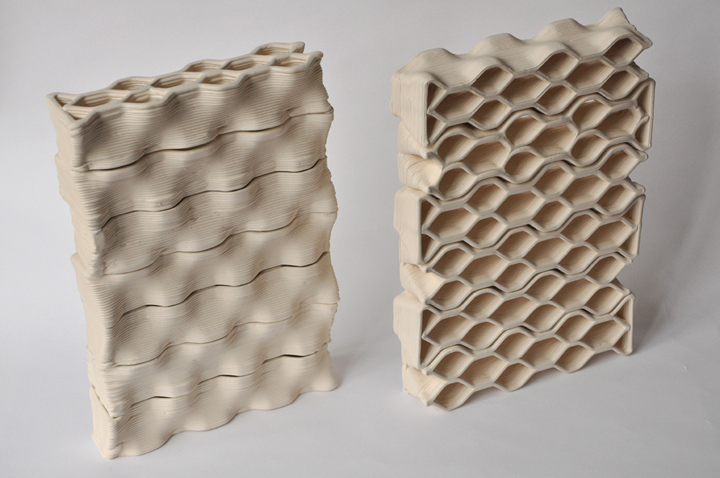

During the residency four potential applications were tested:

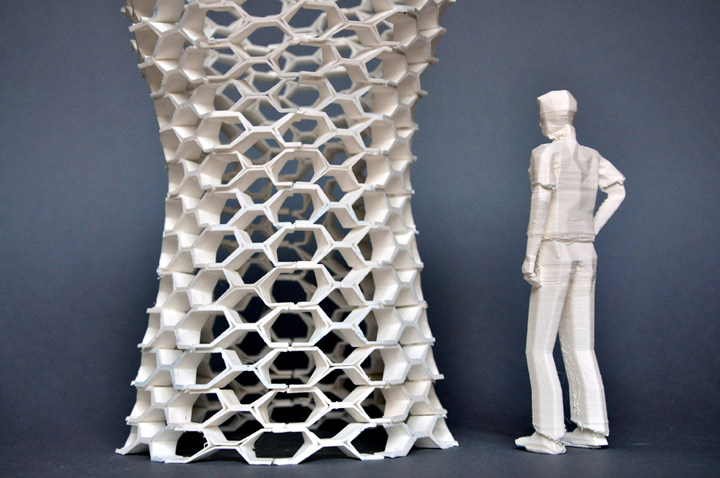

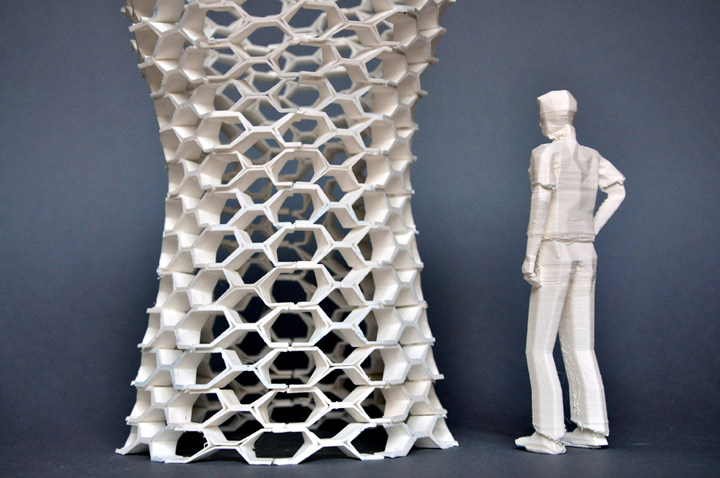

1) columns and towers

2) domes of interlocking bricks

3) vertical tiling

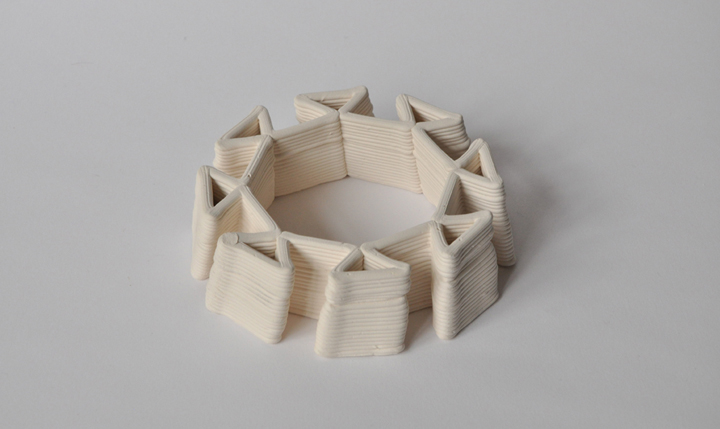

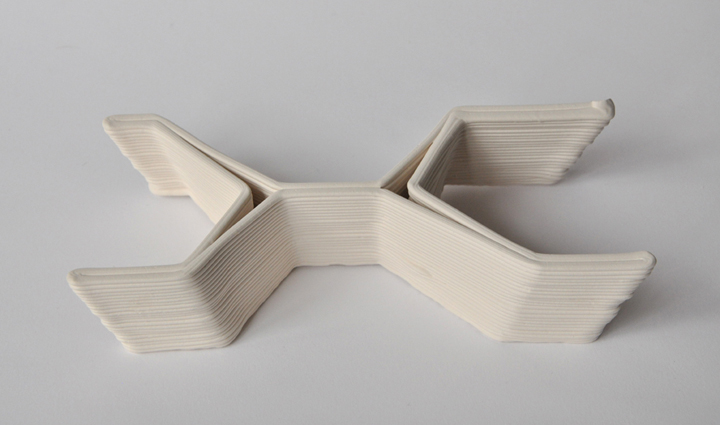

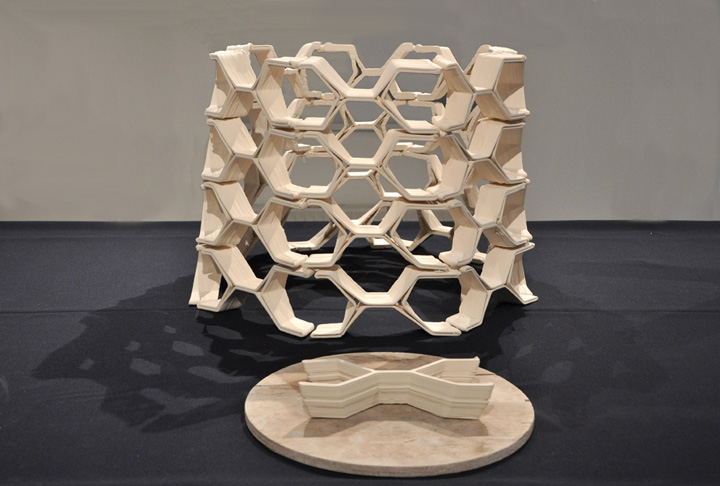

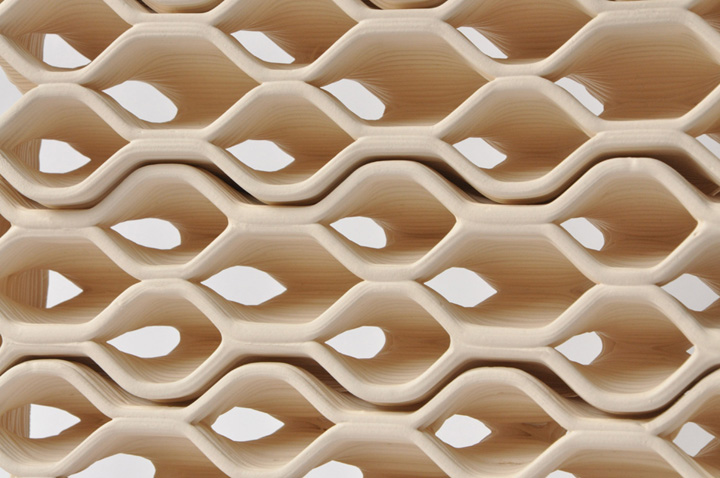

4) modular honeycomb stackable bricks

This research aimed to test the system with two design/ fabrication systems: uniformity (the same brick printed multiple times) and variation (unique bricks that create a specific form). The next phase of research will investigate additional “byte” materials.