“Open Factory”: where the history of local industry and enterprise is organized for visitors to experience. Yamanashi Prefecture has played a major role in the Japanese jewelry industry as a crystal production center through the ages. These days, one third of Japanese jewelry is produced in Yamanashi Prefecture, which is bustling with many jewelry-related companies. The client for this project is a jewelry manufacturer with a history of carrying out all aspects of jewelry manufacture, from design to production, in Yamanashi Prefecture.

Our client wanted to be able to show the general public the jewelry manufacturing process. So, we suggested they showcase their corporate history in addition to the manufacturing process in a location that not only allows visitors to enjoy the actual manufacturing site, but lets them become more familiar with and feel closer to manufacturing. The manufacture of jewelry can be broadly divided into five steps: “design” → “prototype” → “wax” → “casting” → “finish”. We found some very attractive and valuable materials within this process.

“Tens of thousands of designs” created by designers. “More than 40,000 jewelry prototypes (molds)” individually handmade by craftsmen. “Tens of thousands of rubber-type pieces” made of silicon to be used in mass production. This vast collection of materials is usually kept hidden from the public; however these materials are valuable in showcasing corporate history and cannot be imitated by others.

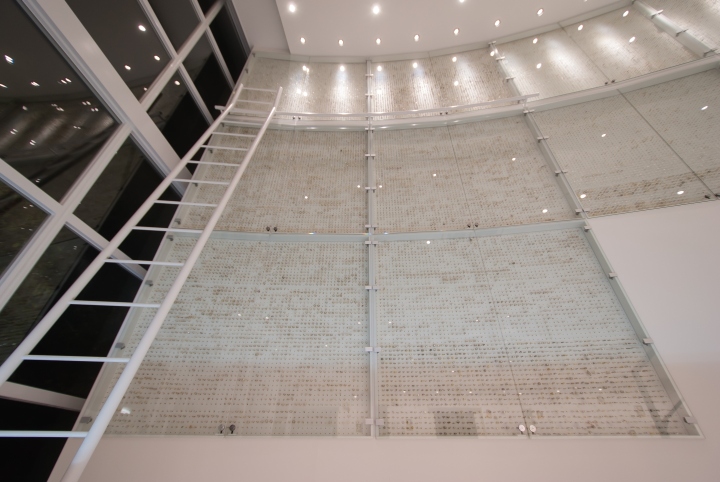

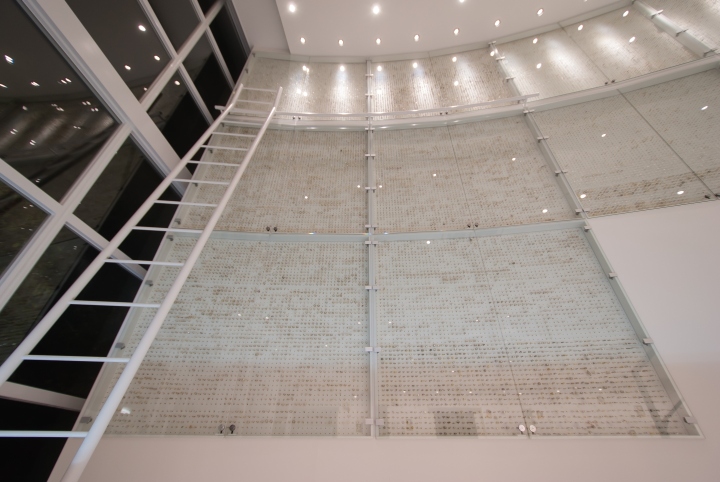

We designed a space in which these materials could be organized and showcased effectively utilizing walls. More specifically, we carefully selected exemplary designs from the “tens of thousands of designs”, created panels, and filled a whole wall as a drawing wall. We created candy bar-shaped holes in a wall in which to insert and showcase the “more than 40,000 jewelry prototypes (molds)”.

We prepared a wall where “tens of thousands of rubber-type pieces” are stacked on bookshelf-like shelves. We proposed that by telling the corporate history and trends in jewelry utilizing many materials that will continue to be indispensable in jewelry manufacturing in the future, visitors would be able to closely feel the corporate history, the history of the manufacturers who have worked here, and the trends in jewelry over the decades.

The actual use of these materials in manufacturing operations blurs the gap between an actual working plant and a visitor’s tour route and is intended to narrow the distance between the manufacturer and visitors. By organizing these materials, produced over a long period of time, which are indispensable in jewelry manufacturing and exhibiting them in a new manner, they will begin to shine strongly and beautifully even after having left the hands of the craftsmen.

This facility, as the “LUCKY Open Factory” name suggests, is an open factory where craftsmen and visitors share the same location and where visitors can experience the history of the local jewelry industry and jewelry companies. As well as playing a role in corporate branding, we believed this facility would lead to the revitalization of the local jewelry industry.

Designed by Noriaki Takeda + Ikuma Yoshizawa / PROCESS5 DESIGN Co.Ltd

Photography by PROCESS5 DESIGN Co.Ltd

Add to collection