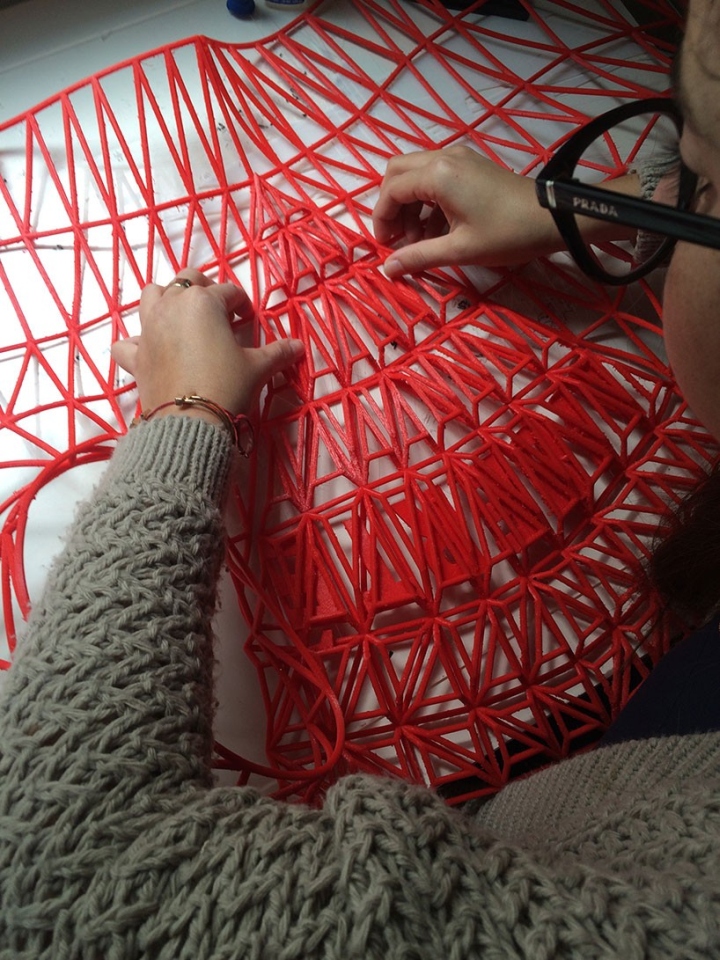

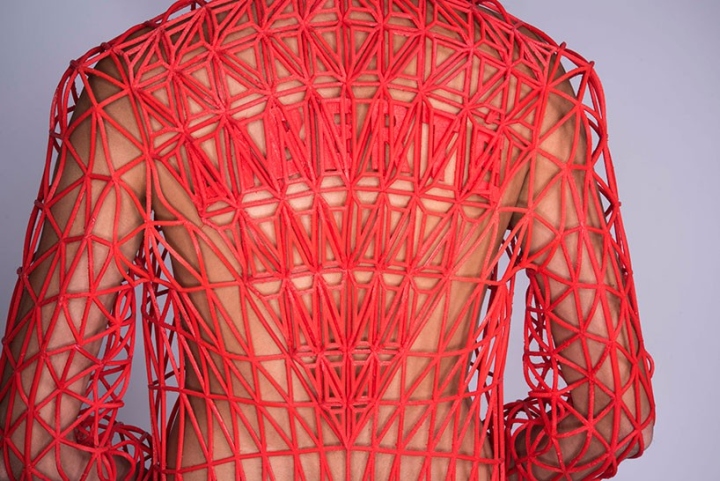

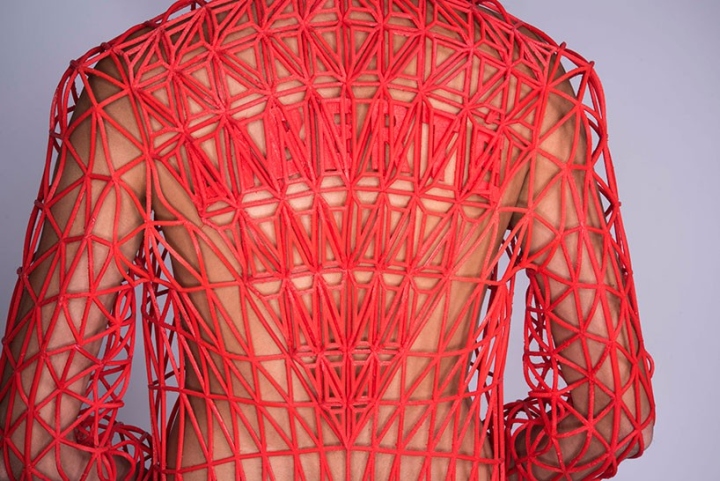

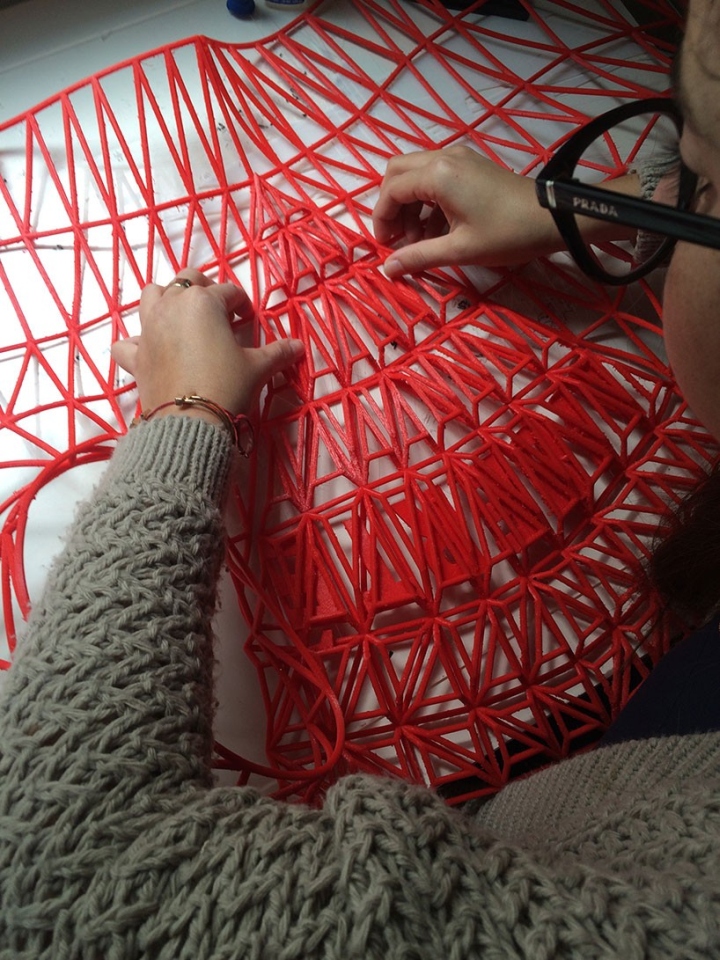

For her fashion graduate collection at Shenkar, Danit Peleg wanted to do something very different. She skipped the sewing machines and fabrics, and went straight towards 3D printing machines. It was a struggle, because she barely knew anything about the technology, and creating entire dresses from home scale 3D printers hasn’t really been done yet. Influenced by triangular painting compositions, her first piece was a red jacket. Using 3D rendering software called blender, just produced files that Danit started experimenting with a variety of materials and printers. Alongside the help of 3D printing experts Techfactoryplus and XLN, she got her hands a different printers polyactic acid plastics (PLA).

The material turned out not her liking because it was brittle and not very flexible. After nine months of experiments and developments, she found herself Filaflex, a strong, very flexible plastic, with which she printed her red jacket. Expanding on her first piece, she designed more elaborate textiles, she managed to create a full collection. It took 2000 hours to print using witbox, household 3D printers, and includes shoes for each piece. Danit Peleg hopes the fashion industry embraces 3D printing for its customization and ability to manufacture clothing anywhere, and looks forward to a time when clothing can simply be printed at home.

Design: Danit Peleg

Photo courtesy of Daria Retiner

via designboom