Until the general modernization of the Deutsches Museum in 2023, the former ‘Forum der Technik’ will be used as a concert and events venue with a Restaurant and a Dance Music Club. The task of the architects was to achieve the vision of a unique spatial and acoustic experience together with the developer. Hence an overall spatial concept that fulfills both high artistic and aural standards was generated. The british manufacturer ‘Void’ has conceived a personalized audio system for this project. Similar to a concert hall that harmonizes with the specific requirements of an orchestra, this system can only perform to its full potential within the circumstances it was designed for. The 600m² large music club is organized into two dancefloors of different sizes and a bar area. A technico-functional aesthetics of timber and steel dominates the 35m long and 8m wide first dancefloor ‘Blitz’.

In collaboration with the acoustics expert, the architects have developed modular dance niches that fit in with the existing column grid while also offering spatial division. Flutter echoes and propagation delays triggered by parallel surfaces are avoided through tilting the side and back walls. What is more, the personalized wall and ceiling elements, which were optimized specifically for electronic music, contribute a great deal to the acoustic quality of the venue. A particular focus lies on the geometry of the tilted back walls. While the front edges follow a straight triangular pattern, the single elements of the grid are developed into concavely curved pockets of different depths. This allows for the sound to refract and disperse in all directions when it hits the surfaces. The implementation of the product ‘BauBuche’ has proven to be highly adequate.

In addition to the ‘warm’ sound of timber, the high bulk density of the beech has a positive impact on the acoustics as well. In this context it was essential to find a structurally resistant material so that the rather thin crosspieces do not break off. A parametric 3D Modell conceived by the architects has allowed for various aesthetic and performance tests and evaluations while also facilitating the decision making and optimization process. At this stage, the carpenter has contributed by manufacturing multiple 1:1 prototypes. The other surfaces inside the club are characterized by a special perforation with sound absorbing properties for various frequencies and thus help lowering the reverberations.

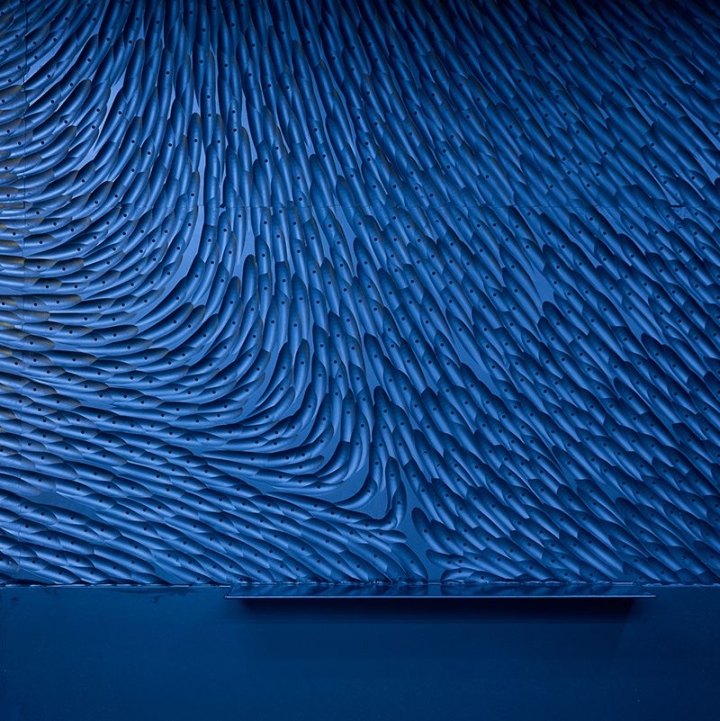

The parts of the cladding close to the floor and in front of the pillars, as well as the cavities within the walls are developed as low-frequency resonators in order to avoid the ‘hum’ of the bass. The lighting concept has been achieved by rather unusual means. The light effects are greatly comprised of classical theatre, stage and discoteque elements from the 70s and 80s which have been deliberately placed in the foreground. However, both their aesthetic and the warm light tones allow them to integrate into the creative concept. The second dance floor, ‘Plus’, is acoustically isolated and speaks its own design language. Without a noticeable beginning or an end, a continuous river of ‘recessions’ is drawn over the walls. This recessing landscape is brought to life by the light that changes to the sound of music.

The visitor dives into a world of music, light and abstract shapes. We developed an algorithm for spreading more than 10.000 ‘valleys’ and ‘ridges’ over a length of 25m. Its shape is based on the behaviour of flocking birds and swarming insects. At no point does the pattern repeat itself. What is more, the algorithm has also been used to create milling rails of a total length of 6,5km for the CNC-machines to follow through. The black laquered MDF has its acoustic justification as well – through its irregular interruptions it accounts for the necessary acoustic diffusion. The degree of perforation and the thickness of the layers vary bringing about an even sound absorbtion over the entire frequency spectrum.

One of the biggest challenges during the short planning period of four months was to develop an efficient process for the fabrication and coordination of the project implementation. Due to the high level of complexity of the building elements only few plans have been drawn. A digital 3D modell has proven to be essential in the decision making process with the clients from the very beginning. A highly advanced phase was reached by working together with the planning specialists and executing companies so that all the necessary files and documents for the CNC fabrication could be exported straight from the 3D model. This central 3D file was accessible for everyone involved with the project and it was even employed on site for coordination.

Design: Studio Knack & Simon Vorhammer

Photography: Simon Vorhammer