As sustainability becomes a more prevalent and necessary topic in the architecture and design industry, new means of production need to be explored. The DB Schenker’s Upcycling Hub in Singapore, designed by Airlab SUTD, demonstrates the future of manufacturing by presenting novel ways to respond to the climate crisis by recycling waste material. The project sets a platform to challenge our value systems and traditional understanding of waste material, redefining our relationship with waste by creating beautiful furniture with discarded plastic and wood through digital design and sustainable manufacturing methods.

The project started in 2018 with the ambition to create awareness of the circularity in the logistics and supply industry among users and visitors by developing a space from waste material. Initially starting with a brief for the DB Schenker employee lunchroom, AirLab’s goal evolved from the initial brief’s scope to become the “large room.” The Upcycling Hub was designed to showcase the value of waste material. This creates a space to reassess our understanding of waste throughout all supply chain stages from design, production, and consumption through new 3D printing processes.

This new communal space leverages new technologies in Additive Manufacturing and Digital Design, with materials derived from waste upcycled into design pieces that are functional and elegant. Using more than 30,000 plastic bottles, discarded cardboard boxes, foam packages, and wood pallets are given a second life through 3D printing and computer numerical control cutting, producing beautiful furniture and spaces.

The pragmatic layout of the space is organized in three bands: the red wall, where all designs are explained using technical axonometric drawings, addressing the depth and complexity of the processes used during fabrication; the white band at the window side maximizes open views and natural light by the creation of a long table, where delicate pendant lights are 3D printed from biopolymers; the central area, where social activity is developed under the recycled PETG chandeliers; and around inclusive pallet tables, cardboard coffee tables, and foam chairs. It is the first Interior Design in Singapore to implement cutting-edge technologies and digital design processes to repurpose waste into functional and elegant interior spaces paving the path for an entirely new way of conceiving ornament, furniture, and spaces from waste.

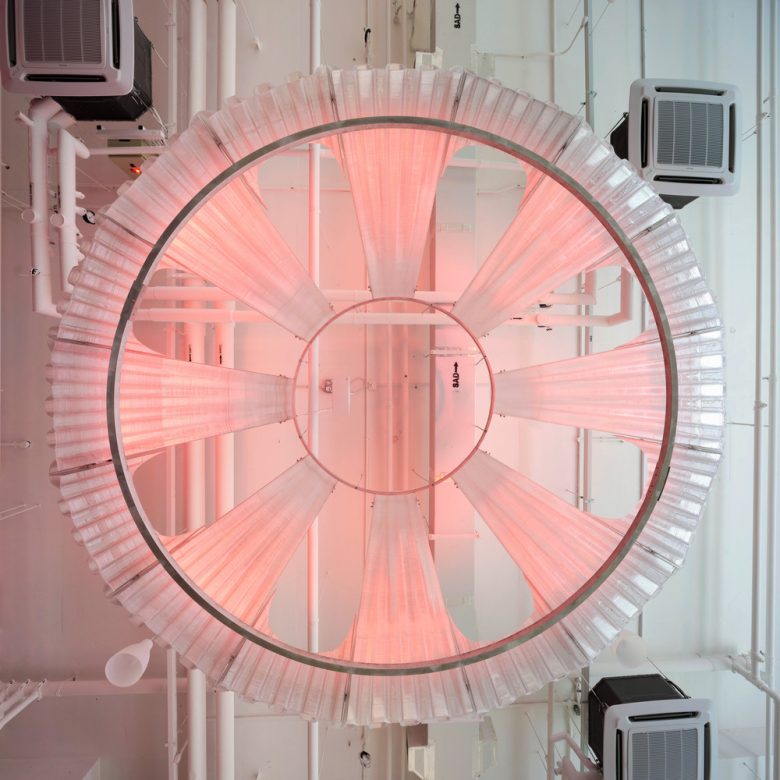

The function of the PET chandeliers was to create spaces within a space and to break down the ample lounge space where employees have lunch breaks and gather into more contained, intimate spaces. Two different types of chandeliers were developed to advance research on the two most distinct polymer printing processes in architecture: Large assemblies of components using FDM desktop printers and a custom-built FDM robotic system. In both cases, recycled PET was tested as the main feed, in filament and pellet form, respectively.

The Gathering Chandelier is a 4m diameter dome-like lighting fixture made of 16 large, robotically printed pieces. Its design was parametrically produced to be manufacturable with single, continuous extrusion. Each component’s bounding box size is around 1.50×0.60, 0.40m. The chandelier was suspended from the ceiling using a top ring. On the bottom part, a compression ring contains the lighting elements. The fabrication process was developed and calibrated by the research team. It consists of a large ABB robotic arm and an extruder fed with 200 kg of recycled PET pellets.

In addition, the four Dining Chandeliers test the creation of a large-scale architectural fixture using conventional FDM 3D printers and recycled PET filament. Four identical 3.5m diameter chandeliers were created for this project. The domes consist of 10 rows of 45 pieces each, accounting for 450 pieces per dome. Each of the 450 components was designed to be printable with a standard FDM printer, with built volumes smaller than 200x200x100mm. The geometry of each tile was based on a minimal Schwarz D (“Diamond”) surface, and it was designed to be printable without supports, producing zero waste in its fabrication. The uppermost element in the dome was explicitly designed to interface with an aluminum ring that suspends the dome from the ceiling. The lighting was solved with an LED ring suspended in the center and projecting light toward the chandelier. Careful attention was given to the connection between components, which was solved with features that concealed nylon nuts and bolts. The total plastic recovered for each of the four domes is 60kg.

Users of the space were also actively involved in the design and assembly process by implementing and expressing their views, especially what waste versus what furniture they wished to see. This engagement provided vital information on how 3D printing fabrication could perform and put power in the hands of users to learn these new techniques. This manifested in employees getting involved in conceptualization, waste sourcing, and assembly, which created a sense of ownership of their co-created space, developing a new appreciation for the materials used.

This project demonstrates how materials deemed useless and destined for landfills can be repurposed into functional and beautiful design objects. Furthermore, the Upcycling Hub is an educational tool to inspire users, designers, and younger generations in experimentation. Where waste has plagued decades of modern societies and is often ignored rather than addressed head-on, the DB Schenker Upcycling Hub challenges this dogma by intending to find a new lease of life for the waste produced in their business. Successfully executing this enabled their users to feel empowered to find future solutions to the waste crisis we face daily with today’s technologies.

The client is deeply proud to showcase this new space to their international branches as an emblem of sustainability and a clear testament to the possibilities when one commits to the future circular economy. With their participation, The Upcycle Hub has become the first space to showcase a full 5,000 sqft of an upcycled project from design to execution. It signals how technology and a company’s commitment can make sustainability possible. Furthermore, using waste material has rejuvenated users’ collective sense of ownership of space. With this new sense of awareness, they can now better understand, appreciate, and participate in constructing sustainable spaces.

Architects: AIRLAB

Project Lead: Carlos Bañón

Project Team: Carlos Bañón, Félix Raspall, Sourabh Maheshwary, Wan Mengcheng, Simon Rocknathan, Tay Boon Kiat, Kwang Kai Jie, Megan Chor Xin Yi, Tai YiJie, Alba Lombardía Alonso, Nahaad Vahid, and Cosmo Wezembeek

Photographs: Fabian Ong