A brass counter in a Fred Segal beauty shop, a handsome headboard in a Cleveland hotel: Chemetal metal finishes go into the hospitality industry’s furniture, wall panels, accents, strips, inlays and more. The 50-year-old, family-owned Massachusetts manufacturer sources metals around the globe and, in 2016, doubled the facilities where its artisans age, abrade, patina, brush and burnish it.

Frame spoke with Chemetal creative director Geoff Schaefer about how the brand’s products are contributing to hospitality design initiatives all over the globe.

Where in hospitality are designers specifying Chemetal?

GEOFF SCHAEFER: Just about everywhere. Chemetal is not always a featured material, it gets along well with others. You’ll find it hanging out in the background, adding to the design intent, like a shade of brass inlaid in a headboard, a strip of reflective metal that enhances wood millwork, or a column wrap that grounds a space that might otherwise be ‘too modern’. Whatever mood design professionals are going for, with over 200 designs, Chemetal can create it.

What do Chemetal products contribute to hospitality interiors?

Just as hotels are where travellers from all over the world come together, they are also where interior design market sectors collide. A lobby is a coffee shop, workplace, restaurant and branded environment. Designers now face design spaces in flux. Hospitality, furniture, corporate, experiential, signage, branding and even residential intersect in hotel spaces everywhere.

And this is a place that Chemetal feels right at home. That’s because designers have long been specifying metal designs and laminates from us in all these commercial settings. It’s a relatively easy way to bring the luxurious, energetic look of metal into a project. And you don’t need to hire a custom metal shop. Budget-wise, it helps too.

How do you and your team follow and anticipate trends?

We look closely at weird stuff like brass door handles and funny pieces of metal most people pass by daily without thinking. But we think, ‘How can we do that on a full sheet of metal?’ It’s work and it’s play. We also talk to people, get on the internet, tear pictures from magazines, watch movies and TV.

Years ago, a couple of us had pre-teen kids watching iCarly, a popular American kids TV show whose set design featured an embossed, aged factory door look that we liked, so we replicated it. That product, Factory, taught us the brushing and aging processes that became the basis, the following year, for some of our most popular materials in aluminum.

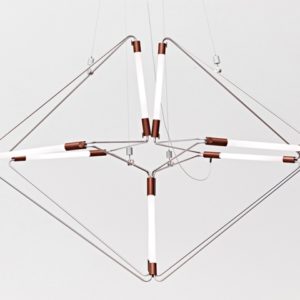

In 2017, you launched a very large collection called Glowing Metals. Why?

Glowing Metals was a massive launch, 36 new designs. We took a hard, mean look at the entire Chemetal Collection and said: Let’s get rid of tired old stuff and replace it with something fresh. And instead of creating designs, let’s create moods. I know it’s a little dreamy to say, but we believe that’s what designers are looking for: moods.

Add to collection